Leaf Spring Hole ID Measurement Machine

The machine is designed for contactless scanning and geometrical parameters measurement of the leaf springs holes.

MODELS

RF096-30/75-120

Measurement range, mm :..........................30...75

Hole depth, mm:......................................up to 120

Accuracy, mm:...............................................±0.04

Measurement speed, parts/s.................programmable, depending on depth

SPECIFICATION :

| Name of parameter | Value |

| Measured diameters, mm | 30...75 |

| ID measurement accuracy, um | ±0.04 |

| Angle scan resolution, points for turnover | 3200 |

| Hole depth measurement range, mm | 120 |

| Linear translation accuracy, mm | ±0.05 |

| Linear translation resolution, mm | programmable, from 0.02 |

| Laser sensor linearity, um | ±20 |

| Laser sensor resolution, um | 5 |

| Laser sensor sample frequency, kHz | 10 |

| Laser sensor power, mW | 1 |

| Laser safety Class | 2 (IEC60825-1) |

| Interface | Ethernet |

| Power supply, V | 220 |

| Measurement speed, parts/s | programmable, depending on depth |

| Weight (without cables) | 11000 gram |

| Measured parameters | average ID, min and max ID, roundness, conicity, cilindricity |

PRINCIPLE OF OPERATION :

Operation of the machine is based on the scanning of the item inner hole surface by rotating point triangulation laser sensor.

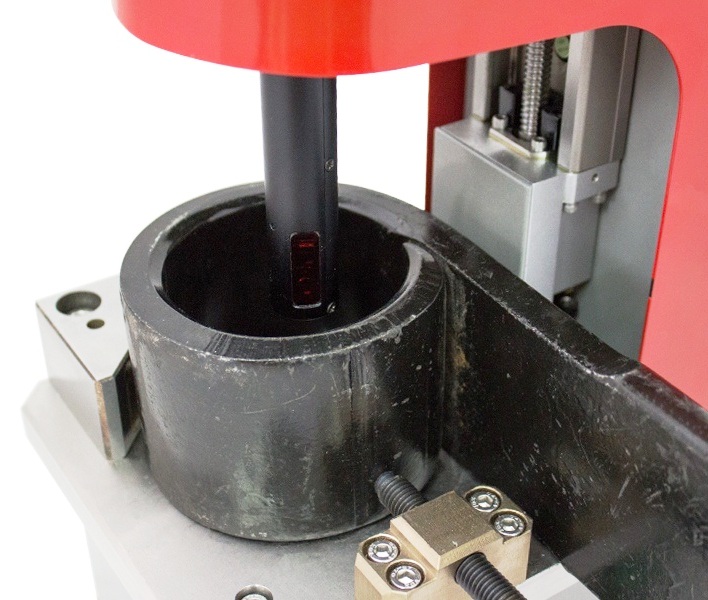

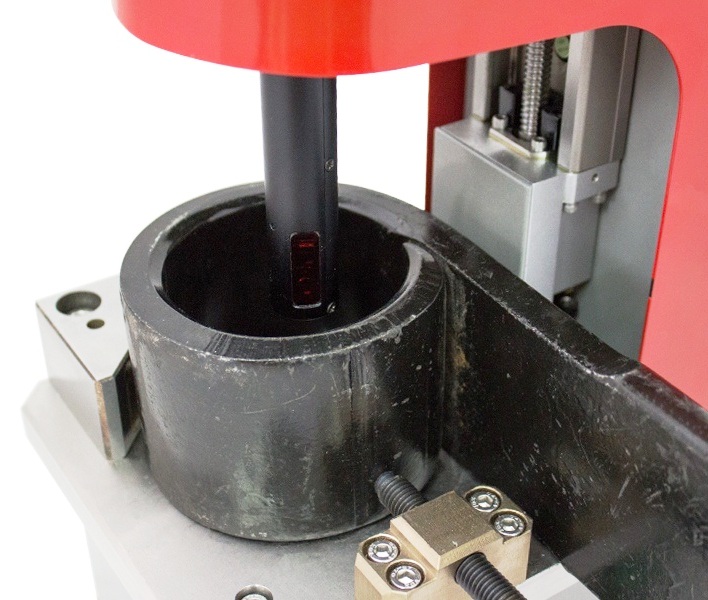

The machine includes a base on which installed a table with the V-block and fixing screw (for placing the measured spring), linear translation mechanism, controller. The linear translation mechanism carries the rotation module on which the laser sensor installed. On the back side of the machine there are two connectors for power and interface.

.jpg)

Figure 1. Front view

.jpg)

Figure 2. Side view

.jpg)

Figure 3. View from above

The machine operates as follows.

The measured spring is placed on the table and fixed in the V-block by screw. At the command from the operator, a laser sensor begins rotation and moves into the control hole. During rotation a laser sensor measures the distance to the surface of the hole in synchronization with the angle of rotation.

The depth of control and number of measured cross sections inside the hole is defined by the software. Radial coordinates of the hole surface are transmitted to the computer for calculating the required hole geometric parameters.

Products

Photo gallery

Contattaci

Non esitate a contattarci, saremo lieti di soddisfare qualsiasi vostra richiesta di informazione di natura tecnica ed economica,relative alla nostra sensoristica.

Chiedi informazioni