RF609-WIFI / Wireless ID measurement sensor for CNC machines

Wireless ID measurement sensor for CNC machines

Laser sensor is designed for non-contact measurement of geometric parameters of holes (diameter, ovality, roundness)

Laser probes RF609-Wi-Fi Series

| RF609-Dmin/Dmax-L-Wi-Fi | -9/19- | -16/48- | |||||||||||||

| Diameter of the laser sensor body, mm | 8.5 | 15 | |||||||||||||

| Range of controlled diameters, mm | 9.2 ... 19 | 16 ... 48 | |||||||||||||

| Depth of controlled holes, mm | on request | ||||||||||||||

| Base distance of the laser sensor, mm | 0.1 | 0.5 | |||||||||||||

| Working range of the laser sensor, mm | 5 | 16 | |||||||||||||

| Laser sensor linearity, % | ±0.05 of the range | ||||||||||||||

| Max. measurement frequency, Hz | 9400 | ||||||||||||||

| Light source |

red semiconductor laser, 660 nm wavelength for both models; blue or UV semiconductor laser, 450 or 405 nm wavelength (BLUE version) only for 16/48 model |

||||||||||||||

| Output power, mW | ≤1 | ||||||||||||||

| Laser safety class | 2 (IEC60825-1) | ||||||||||||||

| Output interface | Wi-Fi | ||||||||||||||

| Power supply, V | 3.7 V, Li-ion battery, 4 mAh | ||||||||||||||

| Power consumption, W | 1 ... 1.5 | ||||||||||||||

|

Environmental resistance:

|

|||||||||||||||

| Enclosure rating | IP67 | ||||||||||||||

| Vibration | 20 g / 10…1000 Hz, 6 hours for each of XYZ axes | ||||||||||||||

| Shock | 30 g / 6 ms | ||||||||||||||

| Operating ambient temperature, °С | -10 … +60 | ||||||||||||||

| Permissible ambient light, lx | 10000 | ||||||||||||||

| Relative humidity, % | 5-95 (no condensation) | ||||||||||||||

| Storage temperature, °С | -20 … +70 | ||||||||||||||

| Housing material | aluminum, brass | ||||||||||||||

| Weight, gram | 650 | 700 | |||||||||||||

NOTE: Parameters of probes (range of controlled diameters, length) can be changed upon request.

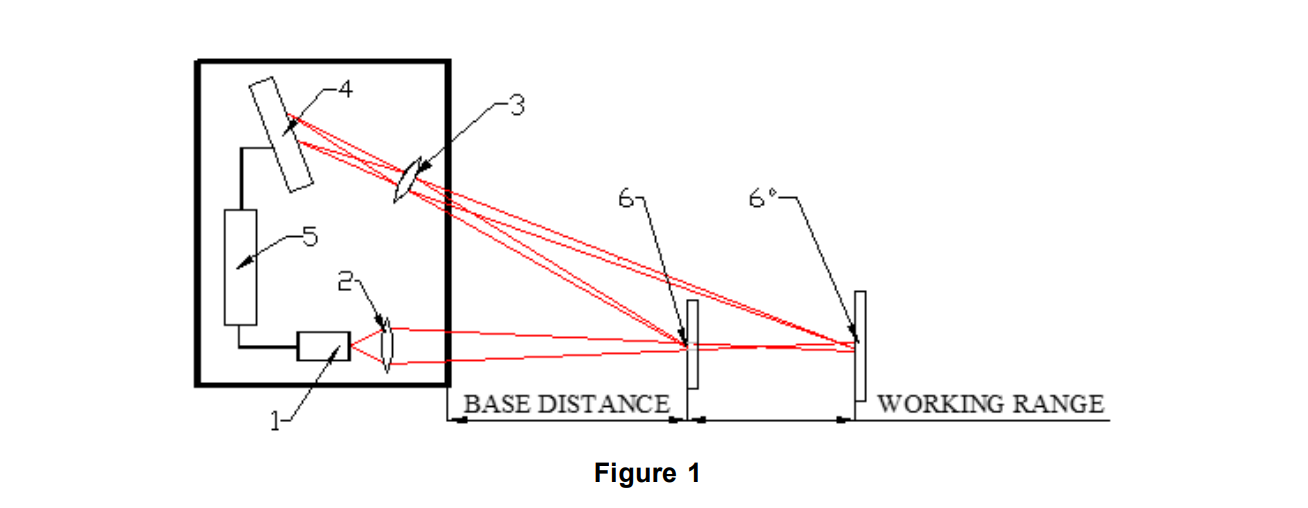

The main component of the probe is a laser sensor. Operation of the laser sensor is based on the principle of optical triangulation (Figure 1). The sensor contains a semiconductor laser (1) with the forming optics (2), the receiving lens (3), the CMOS array (4), and the controller (5).

Radiation of a semiconductor laser is focused by the lens onto the object (6). Radiation reflected by the object is collected by the lens onto the CMOS array. Moving the object (6 - 6') causes the corresponding shift of the image. A signal processor calculates the distance to the object from the position of the light spot on the CMOS array.

The laser sensor is characterized by a base distance (the distance from the probe body to the beginning of the working range) and the working range (the distance measurement range).

The measuring principle is illustrated in Figure 2. The laser probe is inserted into the controlled hole. The probe (or the part) starts rotating at a constant speed. A triangulation laser sensor, which is built into the probe, measures the distance to the hole surface. The resulting set of coordinates is used to calculate the geometric parameters of the hole. Moving the probe along the hole allows you to get the geometric parameters of the hole in different sections and build a 3D model of the inner surface.

Products

Contattaci

Non esitate a contattarci, saremo lieti di soddisfare qualsiasi vostra richiesta di informazione di natura tecnica ed economica,relative alla nostra sensoristica.

Chiedi informazioni